Elcoseal® geosynthetic clay liners (GCLs) are used as a lining system in landfill, liquid waste and water containment structures to form a barrier that prevents contamination of surrounding groundwater. It is also commonly used to contain liquid in effluent ponds, tailing dams, ponds, lakes, wetlands, irrigation canals and channels.

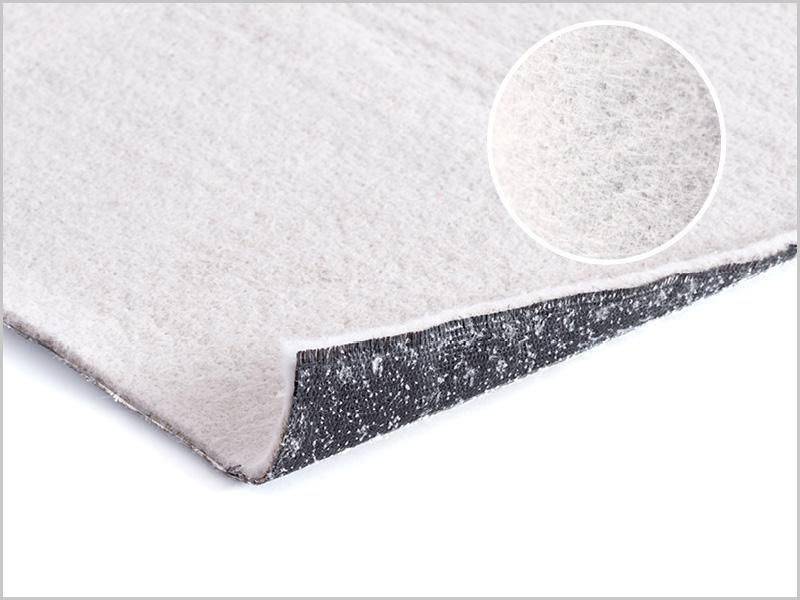

Elcoseal GCL is made in Australia and consists of a layer of high-quality sodium bentonite powder bonded between two or more layers of woven and non-woven geotextiles which are made with high tenacity polypropylene fibres. A needle-punching process reinforces the bentonite layer with thousands of fibres, improving confinement and internal shear strength. An additional heat-treating process called thermal locking secures the needle-punched fibres, further improving strength and performance.

WHY CHOOSE ELCOSEAL?

Elcoseal GCLs have rapid sealing and self-healing abilities due to increased surface area of the powdered sodium bentonite clay which swells when hydrated. In fact, it can swell laterally around holes or punctures so there is less chance of leaks due to installation damage.

Elcoseal allows landfill, and other waste and water containment structures, such as tailings dams, to be built faster and more cost effectively when compared to traditional lining systems. It provides:

- Enhanced reliability due to consistent low permeability performance

- Increased void spacing within the landfill by removing the need for 1-metre-thick compacted clay layer

- Hydraulic protection equivalent to a 1m thick layer of compacted clay layer

- Reduced installation time and waste due to the supply of rolls in custom grades and lengths

- Proven sealing techniques and simple overlap process along the edges, removing the need for a specialist installation crew

APPLICATIONS

Containment Lining & Capping

Reduces the leakage of leachate out of the landfill waste body and prevent water infiltration through the top surface of the landfill. Used in landfill base liners, side slopes and caps to replace or supplement traditional lining systems.

Can also be used in conjunction with gas collection systems to prevent the migration of gases from landfills or contaminated sites.

Allows tailing ponds and rehabilitation projects to be built faster and more cost-effectively in mining. Reduces leakage of contaminant materials from the site and assists mining companies to achieve environmental compliance.

Water Storage Lining

Provides excellent liquid containment in reservoirs, wetlands and irrigation canals, lagoons, effluent and industrial and landscaped ponds due to its’ low permeability, high internal shear strength and easy installation method.