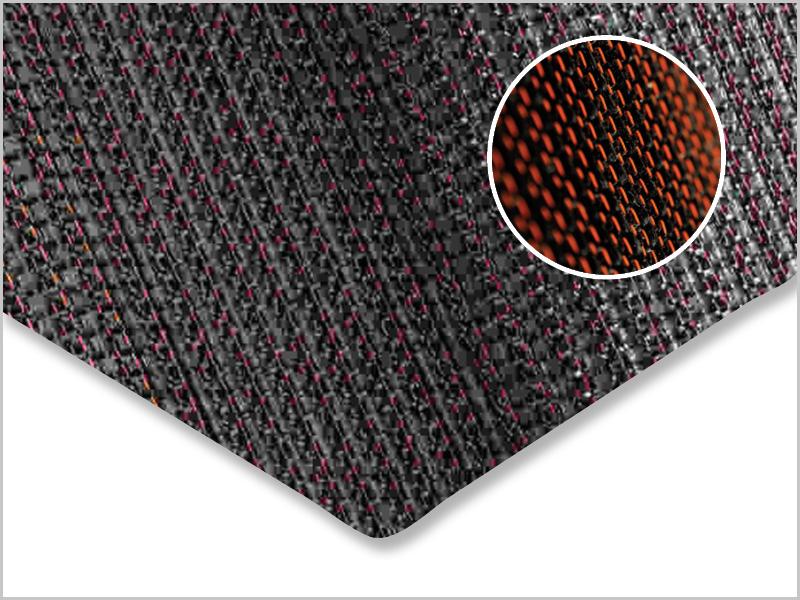

When faced with increasing earthwork costs and challenging ground conditions, Solmax® Mirafi® RSi multi-functional woven geotextile offers a cost-effective construction solution over soft soils. It's unique double layer construction made from high-tenacity polypropylene filament provides superior reinforcement strength and soil interaction capabilities by simultaneously allowing high water flow and soil retention within a roadway system.

Using Mirafi RSi leads to significant improvements in road and subgrade performance with the added benefit of reduced sub-base material volume when constructing over soft soils. It is ideal for use as a base course reinforcement and subgrade stabilisation in roads, railways, runways, haul roads; and for stabilisation of embankments on soft foundations.

WHY CHOOSE SOLMAX MIRAFI RSI?

- Superior separation and filtration capability with effective prevention of aggregate mixing and loss of sub-base material into soft subgrade

- Material cost savings of up to 33% by reducing the amount of base material required

- Unique double layer construction provides a wide range of pore sizes for an excellent separation factor, superior filtration and flow characteristics of a fine to coarse sand layer

- Excellent soil and base course confinement resulting in greater load distribution

- Robust structure that withstands the effects of rough dumping and filling with minimal damage

- High permeability with efficient release of pore water pressure which makes it suitable for installation over soft wet soils

- Easy installation by simply laying and aligning the system

INSTALLATION

Geosynthetic Placement

Place the geosynthetic directly on prepared surface. It is advisable to leave vegetative cover in place to provide a support matting for construction activities.

The geosynthetic should be deployed flat and tight with no wrinkles or folds. The rolls should be oriented as shown on plans to ensure the principle strength direction of the material is placed in the correct orientation. Adjacent rolls should be overlapped or seamed as a function of subgrade strength (CBR).

Prior to fill placement, the engineered woven geotextile should be held in place using suitable means such as pins, soil, staples and sandbags to limit movement during fill placement.

Fill Placement

Fill should be placed directly over the Mirafi RSi geotextile in 200mm to 300mm loose lifts. For very weak subgrades, 450mm lifts or thicker may be required to stabilise the subgrade. Most rubber-tired vehicles can be driven at slow speeds, less than 16 km/h and in straight paths over the exposed geosynthetic without causing damage. Sudden braking and sharp turning should be avoided.

Tracked construction equipment should not be operated directly upon the geosynthetic.

A minimum fill soil thickness of 150mm is required prior to operation of tracked vehicles over the geosynthetic. Turning of tracked vehicles should be kept to a minimum to prevent tracks from displacing the fill and damaging the geotextile.

APPLICATIONS

Ground & Pavement Stabilisation

Mirafi RSi is designed to maximise the use of large site -won materials in haul roads, unpaved roads, temporary roads, loading support platforms and access track construction. It efficiently combines critical functions that reinforce the subgrade, effectively resolving challenges in the most demanding construction conditions and significantly reducing construction costs by minimising the need for imported fill.

Embankments

Solmax Mirafi RSi Range

|

Code |

Description |

Width (m) |

Length (m) |

|

RS380I |

Mirafi RS380i |

4.6 |

100 |